Introduce:

Thread rolling die design plays a vital role in achieving a precise and efficient thread rolling process. Design complexity and related factors greatly affect the quality and performance of threaded components. As the demand for precision engineering continues to increase, it is imperative to explore and optimize thread rolling die designs to meet the changing requirements of the industry. This blog aims to delve into the essentials of thread rolling die design, highlighting key considerations and best practices for improving accuracy and performance.

Learn about thread rolling die design:

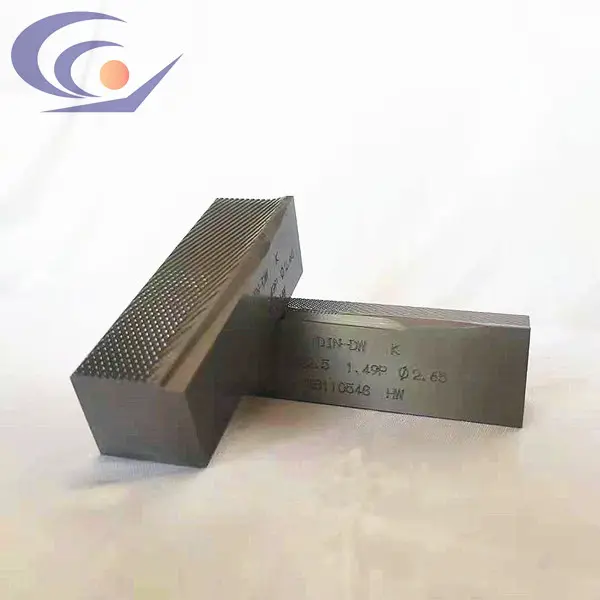

Thread rolling dies are special tools used to form various threads on workpieces through cold forming. By applying pressure to the material, the mold continuously moves the material to create the desired thread shape. The design of these molds greatly affects the final result, limiting considerations such as thread profile, size and overall durability. The best thread rolling die designs strive to maximize productivity, minimize downtime and ensure consistently high-quality threads.

Key factors affecting thread rolling die design:

1. Material selection: Choosing the right mold material is crucial because it determines the durability and life of the mold. Typically, high-speed steels, tool steels, and carbide are favored for their hardness and resistance to wear and fatigue.

2. Mold geometry: Mold geometry, including thread profile, is critical to obtaining accurate threads. The required thread shape, pitch and lead angle must be considered during the design phase to ensure compatibility with the workpiece.

3. Mold Hardness: Strike a balance between hardness and toughness to ensure optimal mold performance. Too much hardness can lead to brittleness, which shortens the life of the mold, while not enough hardness can lead to wear and premature failure.

4. Heat treatment: Appropriate heat treatment technology, such as annealing, tempering, nitriding, etc., can stabilize the internal structure of the mold and improve its wear resistance. Proper heat treatment ensures consistent performance and extends mold life.

Best Practices in Thread Rolling Die Design:

1. Collaboration and Iteration: Productive communication between mold designers, manufacturers, and end users can foster collaboration and ensure that mold designs meet the specific requirements and preferences of the application.

2. Fine-tune the mold profile: Accuracy in designing the mold profile is crucial. Fine-tuning the shape and geometry of the profile can improve thread quality and reduce the risk of defects such as wear, burrs or thread misalignment.

3. Thorough testing and validation: Testing and validating mold design prototypes is critical before mass production. This iterative process helps identify and mitigate potential issues, optimize functionality, and ensure an efficient thread rolling process.

4. Regular maintenance and inspections: Implementing a proactive maintenance program for thread rolling dies reduces downtime and ensures consistent performance. Regular inspections, lubrication and preventive maintenance extend mold life and minimize production failures.

In conclusion:

Achieving optimal thread rolling die design is a key aspect of precision engineering. By considering factors such as material selection, mold geometry, hardness and heat treatment, engineers can ensure the production of high-quality threads. Employing best practices such as collaboration, fine-tuning, testing and regular maintenance enables manufacturers to maximize accuracy, performance and overall productivity. As the demand for precision threaded components continues to grow, designers and manufacturers must embrace continued improvements and innovations in thread rolling die design.

Post time: Nov-30-2023